Wholesale Price Blind Rivet Nuts - Hex Flange Nuts – Zonolezer Detail:

Product name: Hex Flange Nuts

Size: M5-M24

Grade : 6, 8, 10, SAE J995 Gr. 2/5/8

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Black, Zinc Plated, HDG

Norm : DIN6923, ASME B18.2.2

Sample: Free Samples

The flange nut and the general hexagon nut are basically the same in size and thread specification, but compared with the hexagon nut, the gasket and the nut are integrated, and there are anti-skid tooth patterns on the bottom, which increases the nut and the workpiece. Compared with the combination of ordinary nut and washer, it is firmer and has greater tensile force. [1] The specifications of common flange nuts are generally below M20. Because most flange nuts are used on pipes and flanges, they are restricted by the workpiece, and the specifications of flange nuts are smaller than those of nuts. Some flange nuts above M20 are mostly flat flanges, that is, there is no tooth pattern on the flange surface. Most of these nuts are used in some special equipment and special places, and the general sales manufacturers do not have stock. Due to the small size of flange nuts, irregular shapes, and some need to be threaded, there are some obvious defects in hot-dip galvanizing. 1. It is difficult to screw the thread after plating. After hot-dip galvanizing, the residual zinc sticking in the thread is not easy to remove, and the thickness of the zinc layer is uneven, which affects the fit of the threaded parts. It is stipulated in GB/T13912-1992 “Technical Requirements for Hot-Dip Galvanized Layers of Metal Coating Steel Products” and GB/T2314-1997 “General Technical Requirements for Electric Power Fittings”; the external thread of fasteners should be in accordance with GB196 before hot-dip plating. The standard specifies machining or rolling, and the internal thread can be machined before or after hot dip coating. However, in practical applications, customers often require both internal and external threads to have galvanized layers, so people adopt various measures to solve the problem of hot-dip galvanizing of threaded fittings. Such as the back-tapping of the threaded parts after plating; reserving a large matching gap; centrifugal throwing and other methods. Back-tapping can easily damage the coating of the threaded part, or even expose the steel matrix, causing the fasteners to rust. Deliberately increasing the diameter of the nut or reserving the fit gap can easily reduce the fit strength, which is not allowed for high-strength fit. 2. The high operating temperature of hot-dip galvanizing will reduce the mechanical strength of high-strength flange nuts. After hot-dip galvanizing of 8.8 grade bolts, the strength of some threads is lower than the standard requirement; the strength of bolts above 9.8 after hot-dip galvanizing basically cannot meet the requirements. 3. Poor working environment and serious pollution. The hot-dip galvanizing process of fasteners is carried out at high temperature. When the solvent is dried and the workpiece to be plated is galvanized into the pool, a strong irritating hydrogen gas will be precipitated; the zinc pool will be exposed to high temperature for a long time, and zinc will be produced on the surface of the zinc pool. Vapor, the atmosphere of the whole working environment is harsh. Although there are many defects in hot-dip galvanizing of fasteners, due to the thick coating, good bonding strength and long-term corrosion effect of hot-dip galvanizing. It has always been respected in the electric power, communication and transportation sectors. With the great development of electric power and transportation in my country, the development of hot-dip galvanizing of flange nuts is bound to be promoted; therefore, it is necessary to develop automatic centrifugal throwing equipment, improve the hot-dip galvanizing process of fasteners, and improve the quality of hot-dip galvanizing of fasteners. very important.

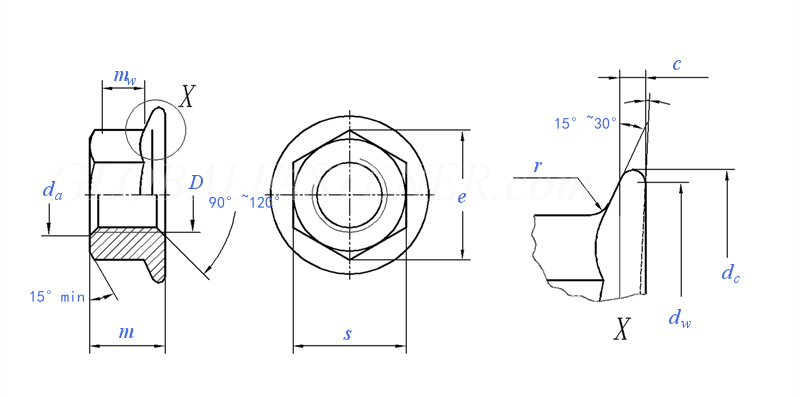

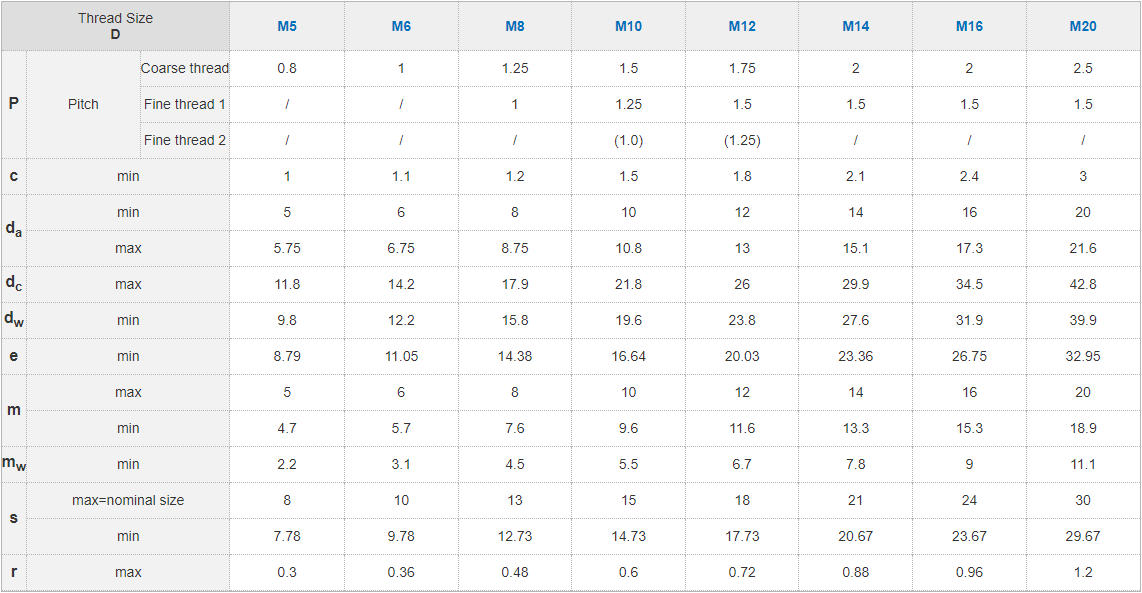

DIN 6923 – 1983 Hexagon Nuts With Flange

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Wholesale Price Blind Rivet Nuts - Hex Flange Nuts – Zonolezer, The product will supply to all over the world, such as: Bolivia, Venezuela, Manchester, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!