Washers are usually metal or plastic. High-quality bolted joints require hardened steel washers to prevent the loss of pre-load due to brinelling after the torque is applied. Washers are also important for preventing galvanic corrosion, particularly by insulating steel screws from aluminium surfaces. They may also be used in rotating applications, as a bearing. A thrust washer is used when a rolling element bearing is not needed either from a cost-performance perspective or due to space restraints. Coatings can be used to reduce wear and friction, either by hardening the surface or by providing a solid lubricant (i.e. a self-lubricating surface).

The origin of the word is unknown; the first recorded use of the word was in 1346, however, the first time its definition was recorded was in 1611.

Rubber or fiber gaskets used in taps (or faucets, or valves) as seal against water leaks are sometimes referred to colloquially as washers; but, while they may look similar, washers and gaskets are usually designed for different functions and made differently.

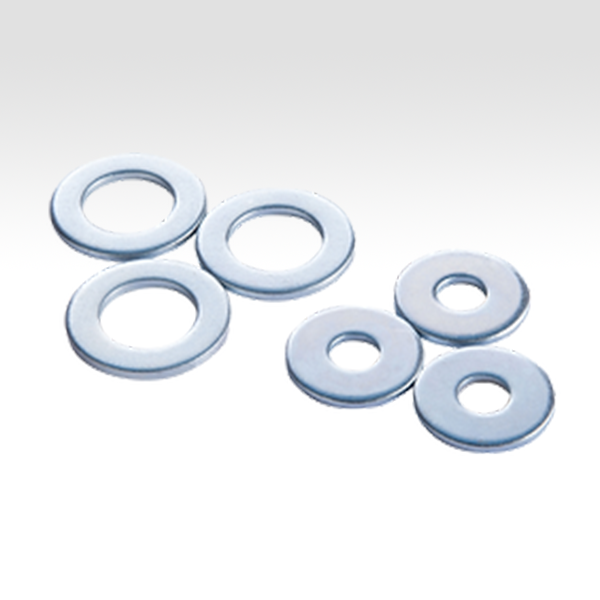

Most washers can be categorized into three broad types;

Plain washers, which spread a load, and prevent damage to the surface being fixed, or provide some sort of insulation such as electrical

Spring washers, which have axial flexibility and are used to prevent fastening or loosening due to vibrations

Locking washers, which prevent fastening or loosening by preventing unscrewing rotation of the fastening device; locking washers are usually also spring washers.