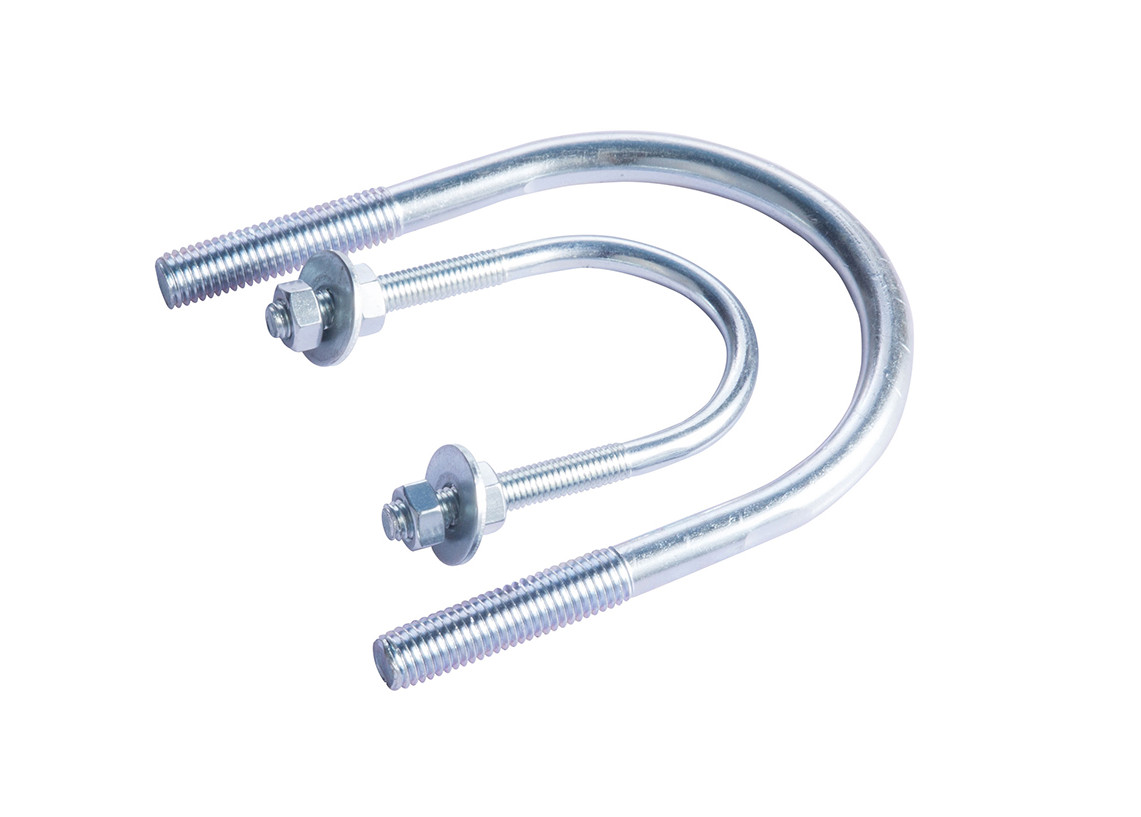

Various precautions for U-bolt and correct use of U-bolt Original title: Various precautions for U-bolt and correct use of U-bolt 1. U-bolt technical standard The general technical conditions of U-bolt should conform to GB 231485" General technical conditions for power accessories". According to GB 70079 "Technical Conditions for Ordinary Carbon Structural Steel", its tensile strength shall not be lower than 372.5N/mm2 (372.5MPa). The threaded parts and components of the U-bolt shall not shrink, and the allowable load of the U-bolt shall not exceed the values listed in Table 3. U-bolt is a non-standard part, so the shape is U-bolt, so it is also called U-bolt. They can be combined with nuts on both ends. It is mainly used for fixing pipe objects such as water pipes, or plate objects such as automobile leaf springs. Because the object they fasten is the same as the person riding the horse, they are called riding bolts. U-bolts are mainly used for construction installation, mechanical parts connection, vehicles, bridges, tunnels, railways, etc. The main shapes are semicircle, square right angle, triangle, oblique triangle, etc. Its density, bending strength, impact toughness, resistance to Compressive strength, elastic modulus, tensile strength, temperature resistance and color. 2. Precautions in the process of installing U-bolts U-bolts are also a common type of pipelines. They are used to fix pipelines and are named after U-shape. The strength and compressive strength of the bolts should be determined according to the environment. The materials are iron, carbon steel and stainless steel , commonly used in carbon steel, can be used in automobiles, mainly used in trucks, its function is to stabilize the chassis and frame, and can also be used for electrical accessories, etc. The U-bolt is a small piece, but it does a big job. When choosing good quality, pay attention to the treatment of surface rust or oil pollution, keep dry after treatment, do not touch sundries, and ensure correct operation and tight connection. The friction surface of the components treated before installation is not allowed to be stained with oil, soil and other sundries during installation. When installing, keep the friction surface of the parts dry and do not work in the rain. Before installation, the deformation of the connecting steel plate should be strictly checked and corrected, and it is strictly forbidden to hammer the bolt on the bolt to prevent the bolt from being damaged. 3. The inner radian of the U-bolt is very important. The U-bolt is a non-standard part and its shape is U-shaped, so it is also called a U-bolt. They can be combined with nuts on both ends. They are mainly used to install pipe objects such as water pipes or thin plate objects such as automobile leaf springs. They are called riding bolts because they are fastened to the same object as a person on a horse. U-bolts are mainly used for construction installation, mechanical parts connection, vehicles, bridges, tunnels, railways, etc. The main shapes are semicircle, square right angle, triangle, oblique triangle, etc. Its density, bending strength, impact toughness, resistance to Compressive strength, elastic modulus, tensile strength, temperature resistance and color. The inner radian of the U-bolt is very important. It requires that the radian of the U-bolt be naturally consistent with the radian of the installed pipe diameter, and it should approach and wrap the pipe diameter that needs to be fixed. The u-bolt is a small part, but it does have a big impact. When choosing good quality, attention should be paid to the treatment of surface rust or oil pollution, keep dry after treatment, and do not touch sundries to ensure correct operation. Fourth, the correct use of U-bolt U-bolt is a commonly used metal expansion screw, expansion screw wedge friction angle grip, promote expansion, to achieve a fixed effect. Tapered head screws are on the screw head. Some cylindrical cutouts are wrapped in iron (steel), iron (steel), etc. more than half of the hole, connect them together, then lock the nut, pull the nut to the wall, taper for metal cylinder, cast iron cylinder liner It is generally used for protecting columns, sunshades, air conditioners and other materials to be fixed on cement, bricks, etc. The bolt is encased in an annular tube, which creates a hole in the wall when used. The anchor bolt is placed in this hole, and when the bolt is tightened, the annular tube is squeezed and stretched. In this way, the bolt is stuck in the hole and plays a fixed role. The method of secondary pouring can be used, that is, the bolt holes of the appropriate size can be reserved when the foundation is poured. Thread is a shape with a uniform helical protrusion on the outer surface or inner surface of a U-shaped bolt. According to its structural characteristics and uses, it can be divided into three categories: Ordinary thread: The tooth shape is triangular, which is used to connect or fasten parts . Ordinary thread can be divided into coarse tooth and fine tooth according to the pitch, and the connection strength of fine tooth thread is higher. Transmission thread: the tooth shape has rectangular, saw-shaped, trapezoidal and so on. Sealing thread: mainly used for sealing connection, mainly pipe thread, tapered thread and tapered pipe thread.

Anchors are of the following types:

(1) Expansion anchor bolt

Expansion anchor bolts, referred to as expansion bolts, use the relative movement of the cone and the expansion sheet (or expansion sleeve) to promote the expansion of the expansion sheet, generate expansion and extrusion force with the concrete on the hole wall, and generate pull-out resistance through shear friction. A component that realizes the anchoring of the connected piece. Expansion anchor bolts are divided into torque control type and displacement control type according to the different expansion force control methods during installation. The former is controlled by torque, and the latter is controlled by displacement.

(2) Reaming type anchor bolt

Reaming type anchors, referred to as reaming bolts or grooving bolts, are re-grooving and reaming of the concrete at the bottom of the drilled hole, using the mechanical interlock between the concrete bearing surface formed after reaming and the expansion head of the anchor bolt. , a component that realizes the anchoring of the connected piece. Reaming anchor bolts are divided into pre-reaming and self-reaming according to different reaming methods. The former is pre-grooving and reaming with a special drilling tool; the latter anchor bolt comes with a tool, which is self-grooving and reaming during installation, and the grooving and installation are completed at one time.

(3) Bonded anchor bolts

Bonded anchor bolts, also known as chemical bonding bolts, referred to as chemical bolts or bonding bolts, are made of special chemical adhesives (anchoring glue) to glue and fix screws and internal threaded pipes in the drilling holes of concrete substrates. The bonding and locking function between the adhesive and the screw and the adhesive and the concrete hole wall to realize a component that is anchored to the connected piece.

(4) Chemical planting of tendons

Chemical planting bar includes threaded steel bar and long screw rod, which is a post-anchor connection technology widely used in my country's engineering circles. The anchorage of chemical planting bars is the same as that of bonding anchor bolts, but because the length of chemical planting bars and long screws is not limited, it is similar to the anchorage of cast-in-place concrete bars, and the damage form is easy to control, and generally can be controlled as the damage of anchor bars. Therefore, it is suitable for the anchorage connection of structural members or non-structural members whose static and seismic fortification intensity is less than or equal to 8.

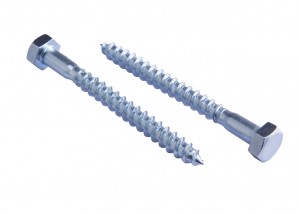

(5) Concrete screws

The structure and anchoring mechanism of concrete screws are similar to wood screws. A special process is used to roll and quench a hard and sharp knife-edge thread screw. During installation, a straight hole with a smaller diameter is pre-drilled, and then the screw is screwed in, using the thread and hole. The occlusal action between the wall concrete produces a pull-out force and realizes a component that is anchored to the connected parts.

(6) Shooting nails

Shooting nail is a kind of high-hardness steel nails, including screws, which are driven by gunpowder, into concrete, and use its high temperature (900 ° C) to make the steel nails and concrete integrated due to chemical fusion and clamping. Realize the anchoring of the connected parts.