Product name: Spring Lock Washer

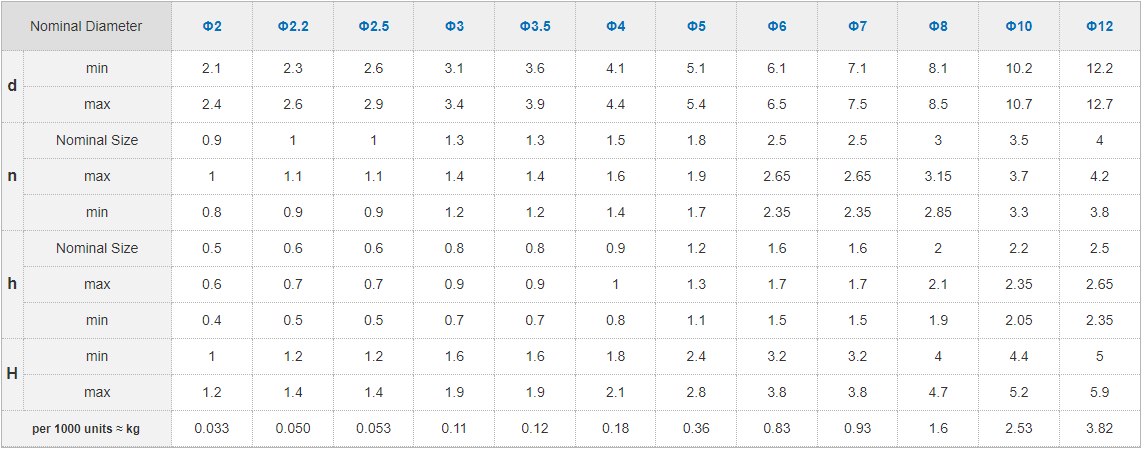

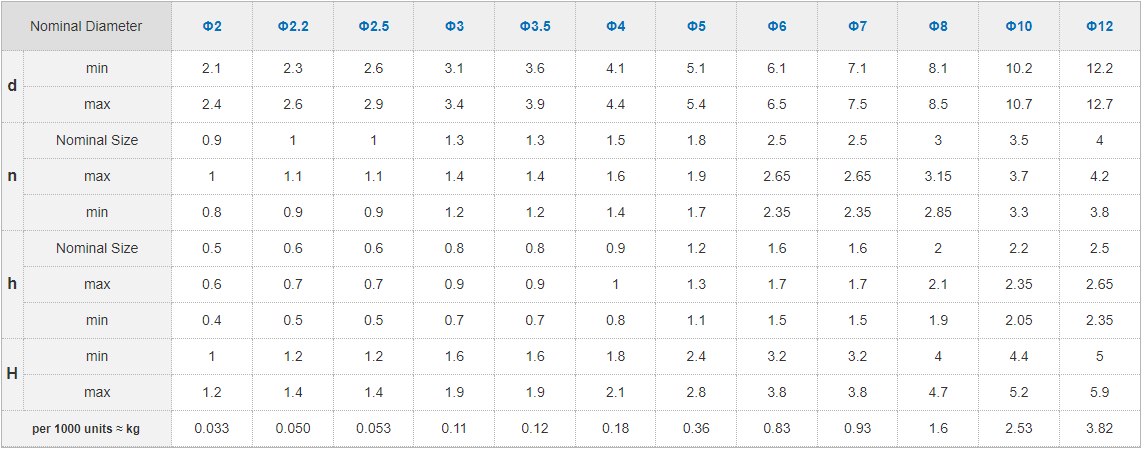

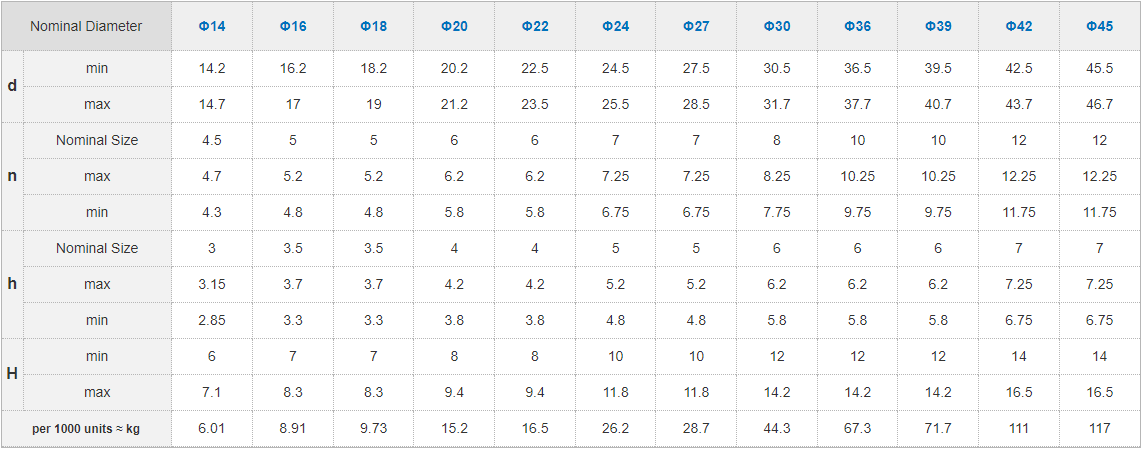

Norm: DIN127B, DIN7980, ANSI/ASME B18.21.1

Size: M1.7-M165

Grade: 430-530 HV

Material: Steel

Surface: Plain, Black, Zinc Plated, HDG

Many people want to save the flat washer or the spring washer in order to save costs. In fact, the flat washer and the spring washer each play an indispensable role in the use of the bolt. Today we are going to introduce to you the flat pads and spring pads. Flat washer, the shape is generally a flat washer, there is a hole in the middle, it is mainly punched out of iron plate, so have you ever learned about how to use the flat washer and its specific function? How to choose a flat pad? The flat washer is used as a part to prevent the bolt and nut from locking. Flat washers are used wherever fasteners are used. How to choose a suitable flat washer? A flat washer is a type of flat washer, which mainly increases the contact area between screws and some large equipment and tightens it. When using a flat washer, it is often suitable for nuts and nuts to be used in conjunction with each other. It must be in the most effective sealing time, and have the necessary important characteristics: 1. In the case of relatively harsh environment, it should be said that the flat gasket should be sealed, when a certain temperature and pressure are not easy to occur during the working time leaked. 2. When the flat gasket is connected to the contact surface, it is necessary to better ensure the sealing, just like the good effect. 3. Under the influence of temperature when the gasket is under pressure, the anti-wrinkle ability is better, otherwise the screw will be damaged, and there will be hard gas leakage. 4. Do not get infected when using the flat pad. 5. The use of flat pads can be well disassembled. This is the biggest role of choosing flat pads. 6. Remember to ensure normal use at the relative temperature when using the flat pad. In order to better use the flat pad, when choosing a flat pad, try to choose a flat pad with anti-rust and anti-corrosion material dip-plating, which not only saves time and effort, but also the role of the flat pad can be played well. When used with bolts and nuts, the selection criteria of flat washers: 1. When selecting the gasket material, attention should be paid to the electrochemical corrosion problem when different metals are in contact. The material of the flat gasket is generally the same as that of the connected parts, usually steel, alloy steel, stainless steel, aluminum alloy, etc. When electrical conductivity is required, copper and copper alloys can be selected. 2. The inner diameter of the flat washer should be selected according to the larger diameter of the thread or screw, and the outer diameter should be larger if the material to be connected is soft (such as composite material) or matched with the spring washer. 3. When choosing to place the W washer under the bolt or screw head, in order to avoid the interference between the fillet under the head and the washer, a flat washer with an inner hole chamfer can be selected. 4. For important bolts with larger diameters, or in order to increase the anti-extrusion capacity, steel washers should be used. Tension bolts or tension-shear composite bolt connections shall use steel washers. 5. Special gaskets are used for special requirements, such as copper gaskets available for electrical conductivity; sealing gaskets available for air tightness requirements. The function of the flat pad: 1. Increase the contact area between the screw and the machine. 2. Eliminate the damage to the surface of the machine when the spring washer is unloading the screw. When using, it must be: spring washer - flat washer, the flat washer is next to the surface of the machine, and the spring washer is between the flat washer and the nut. The flat washer is to increase the bearing surface of the screw. In order to prevent the screw from loosening, the spring washer provides a certain amount of buffer protection when it is stressed. Although flat pads can be used as sacrificial pads. 3. But more often it is used as a supplementary pad or a flat pressure pad. Advantages: ①By increasing the contact area, the parts can be protected from damage; ②By increasing the contact area, the pressure between the nut and the equipment can be reduced, thus playing a protective role. Disadvantages: ① Flat washers can not play the role of anti-seismic; ② Flat washers also have no anti-loosening effect. The function of the spring washer 1. The function of the spring washer is that after the nut is tightened, the spring washer will give the nut an elastic force and press the nut so that it is not easy to fall off. The basic function of the spring is to give a force to the nut after the nut is tightened, increasing the friction between the nut and the bolt. 2. Flat pads are generally not used for spring washers (except for the use of flat pads and spring washers to protect the surface of the fastener and the mounting surface). 3. Flat pads are generally used in connectors, one of which is soft and the other is hard and brittle. Its main function is to increase the contact area, disperse the pressure, and prevent the soft texture from being crushed. Advantages: ①The spring washer has a good anti-loosening effect; ②The spring washer has a good anti-seismic effect; ③The manufacturing cost is low; ④The installation is very convenient. Disadvantages: The spring washer is greatly affected by the material and process. If the material is not good, the heat treatment is not well grasped, or other processes are not in place, it is easy to crack. Therefore, you must choose a reliable manufacturer. When to use a flat pad and when to use a spring pad? 1. Under normal circumstances, only flat pads can be used when the load is relatively small and the vibration load is not supported. 2. In the case of relatively large load and vibration load, a combination of flat washer and spring washer must be used. 3. Spring washers are basically not used alone, but are used in combination. In the actual use process, due to the different emphasis of the flat washer and the spring washer, in many occasions, the two are matched with each other and used together, which also has the advantages of protecting the parts, preventing the loosening of the nut and reducing the vibration, which is great. s Choice. Application and Failure Form Analysis of Flat Washer Bolts The application is very wide. 1. The main functions of flat gaskets in assembly 1) Provide a bearing surface. When the bearing surface of the bolt or nut is not enough to fully cover the connected parts, the gasket can provide a larger bearing surface; 2) In order to reduce the pressure on the bearing surface or make the Its uniformity When the bearing surface area is too small or the bearing surface pressure is too high, the gasket can reduce the bearing surface pressure or make it more uniform; 3) Stabilize the friction coefficient of the bearing surface when the flatness of the bearing surface of the connected piece is poor (such as Stamping parts), making it sensitive to seizure caused by local contact, resulting in an increase in the friction coefficient of the supporting surface, and the gasket can stabilize the friction coefficient of the supporting surface; 4) Protect the supporting surface when tightening the bolt or nut, there are scratches The risk of injuring the surface of the connected parts, the gasket has the function of protecting the supporting surface; 2. The failure mode of the flat washer combination bolt The failure mode of the flat washer combination bolt--the interference between the gasket and the fillet under the bolt head 1) Failure phenomenon of the flat washer combination bolt An important failure form in application is the interference between the gasket and the fillet under the bolt head, resulting in abnormal torque during assembly and poor follow-up of the gasket; the most intuitive manifestation of the interference between the gasket and the fillet under the bolt head is that the gasket There will be a significant gap on the bearing surface under the bolt head, which will cause the bolt and the gasket to not fit properly when the bolt is tightened. 2) Failure reasons The main reason for the interference between the combination bolt gasket and the fillet under the bolt head is that the fillet under the bolt head is too large, or the design of the inner diameter of the gasket is too small and unreasonable; resulting in interference after the gasket and the bolt are combined.

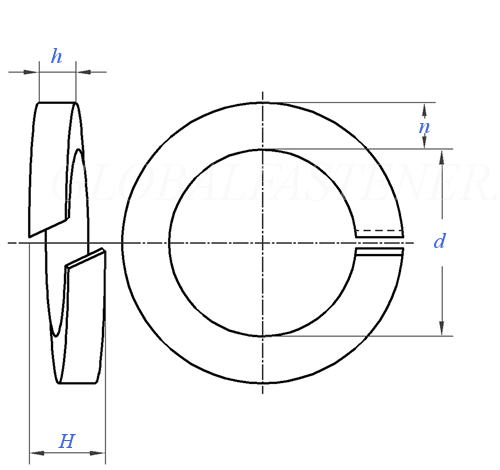

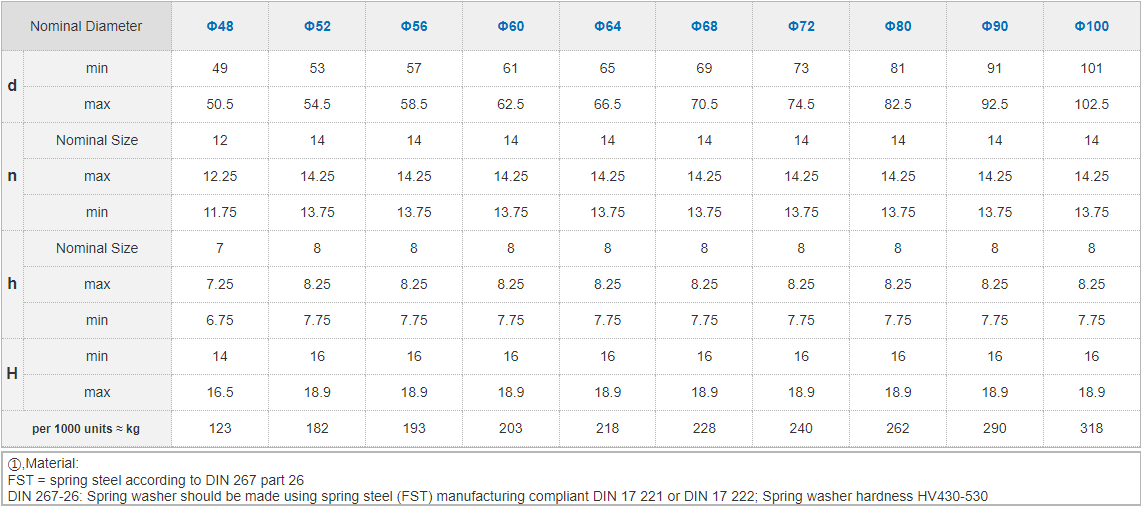

DIN 127 (B) - 1987 Spring Lock Washers, With Square Ends -B type