Professional China Threaded Inserts For Wood - Speed Bar – Zonolezer Detail:

As an important part in the construction industry, full threading plays a key role. In the past fifty years, fasteners have been widely used in the construction industry and some mechanical equipment. Due to the general improvement in the efficiency and strength of building materials, the body weight of buildings is developing in a lighter direction, and the ratio of strength to weight of its constituent materials is also increasing. A building that is too light is not a good thing, its resistance to wind and impact is gradually weakened, so there is a safety hazard when we use these buildings. In the past time, some people thought that a building could be built only by relying on the weight of the building itself and the adhesion of mortar, but this is not the case, any building is not built only by mortar, this time all Mechanical fasteners such as buttons play its role. In order to make up for the structural defects caused by the weight reduction. As the weight of building components becomes lighter, their volume is also reduced, so that the place where the full thread is installed is correspondingly reduced. It is for this reason that the strength of the full thread is required to be increased, and its performance It must be completely predictable, so as to ensure the safety of the building, and also improve the wind resistance and impact resistance of the building. Don’t underestimate the effect of full threading, which sometimes plays a major role.

Anchors are of the following types:

(1) Expansion anchor bolt

Expansion anchor bolts, referred to as expansion bolts, use the relative movement of the cone and the expansion sheet (or expansion sleeve) to promote the expansion of the expansion sheet, generate expansion and extrusion force with the concrete on the hole wall, and generate pull-out resistance through shear friction. A component that realizes the anchoring of the connected piece. Expansion anchor bolts are divided into torque control type and displacement control type according to the different expansion force control methods during installation. The former is controlled by torque, and the latter is controlled by displacement.

(2) Reaming type anchor bolt

Reaming type anchors, referred to as reaming bolts or grooving bolts, are re-grooving and reaming of the concrete at the bottom of the drilled hole, using the mechanical interlock between the concrete bearing surface formed after reaming and the expansion head of the anchor bolt. , a component that realizes the anchoring of the connected piece. Reaming anchor bolts are divided into pre-reaming and self-reaming according to different reaming methods. The former is pre-grooving and reaming with a special drilling tool; the latter anchor bolt comes with a tool, which is self-grooving and reaming during installation, and the grooving and installation are completed at one time.

(3) Bonded anchor bolts

Bonded anchor bolts, also known as chemical bonding bolts, referred to as chemical bolts or bonding bolts, are made of special chemical adhesives (anchoring glue) to glue and fix screws and internal threaded pipes in the drilling holes of concrete substrates. The bonding and locking function between the adhesive and the screw and the adhesive and the concrete hole wall to realize a component that is anchored to the connected piece.

(4) Chemical planting of tendons

Chemical planting bar includes threaded steel bar and long screw rod, which is a post-anchor connection technology widely used in my country’s engineering circles. The anchorage of chemical planting bars is the same as that of bonding anchor bolts, but because the length of chemical planting bars and long screws is not limited, it is similar to the anchorage of cast-in-place concrete bars, and the damage form is easy to control, and generally can be controlled as the damage of anchor bars. Therefore, it is suitable for the anchorage connection of structural members or non-structural members whose static and seismic fortification intensity is less than or equal to 8.

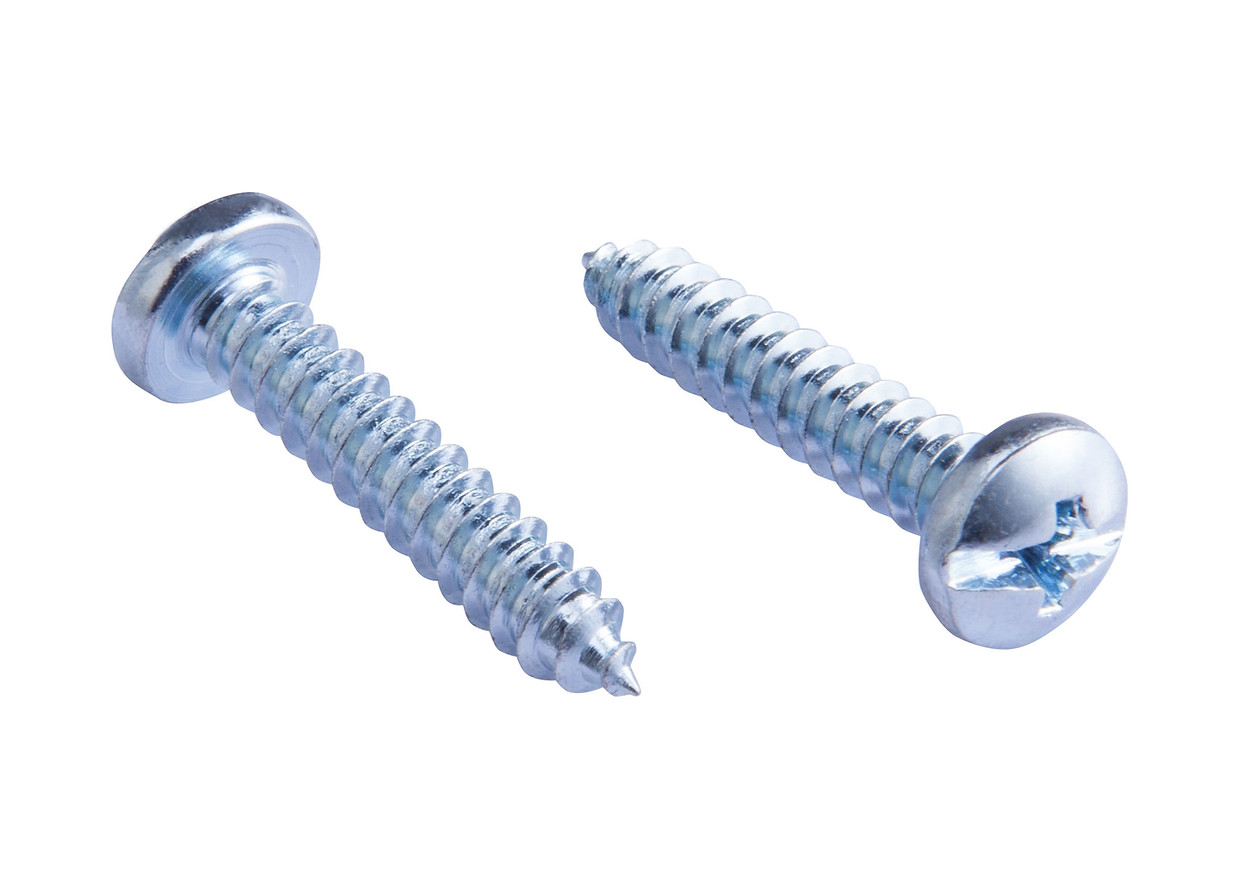

(5) Concrete screws

The structure and anchoring mechanism of concrete screws are similar to wood screws. A special process is used to roll and quench a hard and sharp knife-edge thread screw. During installation, a straight hole with a smaller diameter is pre-drilled, and then the screw is screwed in, using the thread and hole. The occlusal action between the wall concrete produces a pull-out force and realizes a component that is anchored to the connected parts.

(6) Shooting nails

Shooting nail is a kind of high-hardness steel nails, including screws, which are driven by gunpowder, into concrete, and use its high temperature (900 ° C) to make the steel nails and concrete integrated due to chemical fusion and clamping. Realize the anchoring of the connected parts.

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Professional China Threaded Inserts For Wood - Speed Bar – Zonolezer, The product will supply to all over the world, such as: Burundi, Atlanta, Ecuador, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.