Manufacturer for Square Nut - Prevailing Torque Nuts/All Metal Lock Nuts – Zonolezer Detail:

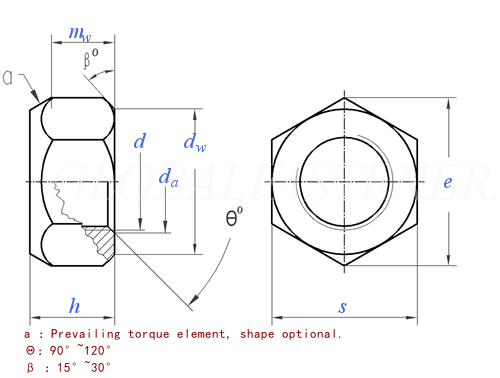

Product name: Prevailing Torque Nuts/All Metal Lock Nuts

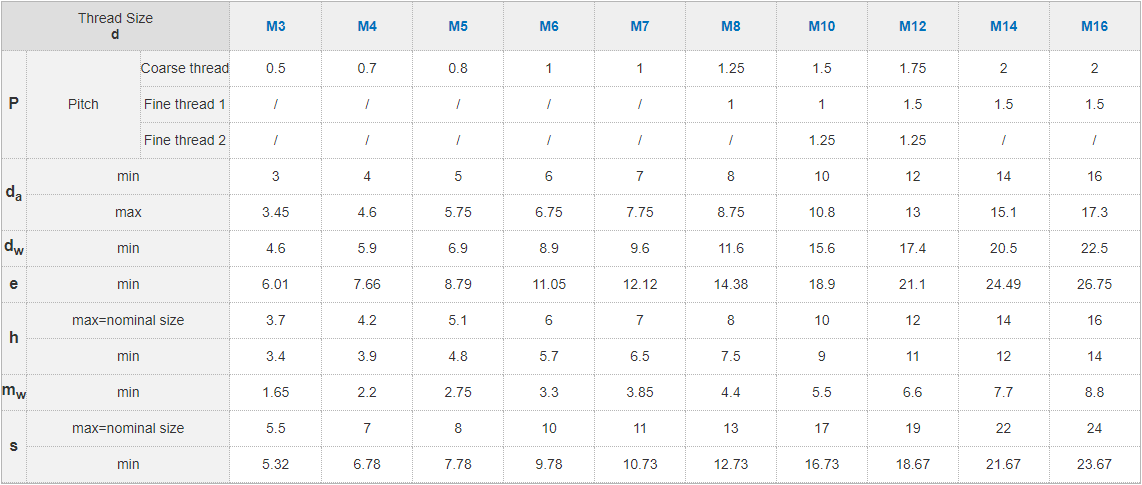

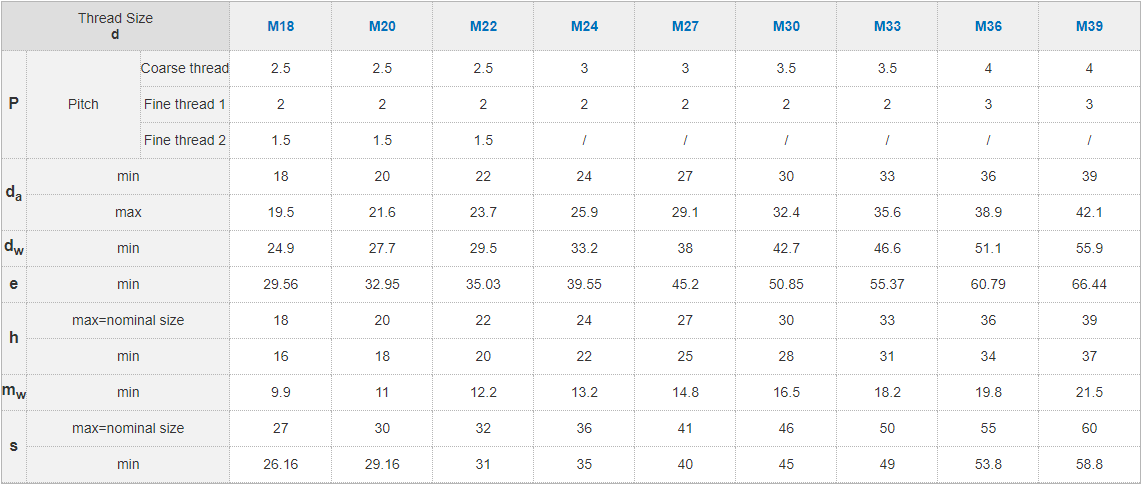

Size: M3-39

Grade: 6, 8, 10 Gr. A/B/C/F/G

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Zinc Plated

Norm: DIN980, IFI 100/107

Sample: Free Samples

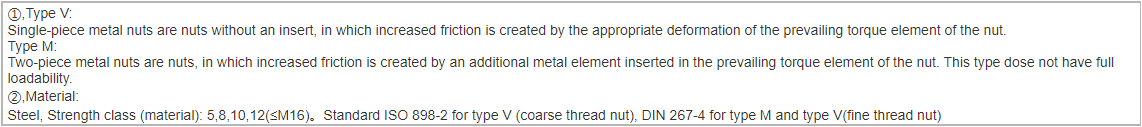

Lock nut locking principle:

The working principle of the nut is to use the friction between the nut and the bolt for self-locking. However, the reliability of this self-locking is reduced under dynamic loads. In some important occasions, we will take some anti-loosening measures to ensure the reliability of the nut locking. Among them, the use of lock nuts is one of the anti-loosening measures. The locking nut generally relies on friction. The principle is to press the embossed teeth into the preset holes of the sheet metal. Generally, the diameter of the square preset holes is slightly smaller than that of the rivet nut. The nut is connected with the locking mechanism. When the nut is tightened, the locking mechanism locks the ruler body, and the ruler frame cannot move freely to achieve the purpose of locking; when the nut is loosened, the locking mechanism disengages the ruler body, and the ruler frame edge The ruler moves.

There are several types of lock nuts:

High-strength self-locking nut: It is a classification of self-locking nut with high strength and reliability.

Nylon self-locking nut: Nylon self-locking nut is a new type of high-vibration and anti-loosening fastening parts.

Swimming self-locking nut: The double-ear seal swimming self-locking nut is composed of four parts: sealing cover, self-locking nut, pressure ring and sealing ring.

Spring self-locking nut: spring clip self-locking nut, which consists of S-shaped spring clip and self-locking nut.

To install the lock nut you will need the following (using the nylon lock nut as an example):

Nylon lock nut, flat washer, 2 sets of wrenches

Install the correct size stainless steel bolt or washer on the threaded end of the stud first. Replace the nuts or bolts that lock onto the bolts by hand until you encounter resistance to the nylon insert.

Tighten the lock nut securely, by using a wrench, replace the original nut and turn clockwise. If the bolt head is tightenable, use the same second wrench to tighten it while tightening the nut.

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for Manufacturer for Square Nut - Prevailing Torque Nuts/All Metal Lock Nuts – Zonolezer, The product will supply to all over the world, such as: Iran, Seattle, Portugal, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!