High definition Button Head Bolt – Hex Structural Bolt/Heavy Hex Bolt – Zonolezer Detail:

Product name: Hex Structural Bolt/Heavy Hex Bolt

Size: M12-36

Length: 10-5000mm or as required

Grade: Type 1, Gr.10.9

Material: Steel/20MnTiB/40Cr/35CrMoA/42CrMoA

Surface: Black, HDG

Standard: ASTM A325/A490 DIN6914

Certificate: ISO 9001

Sample: Free Samples

Usage: Steel structures, multi -floor,high -rise steel structure, buildings, industrial buildings, high -way, railway, steel steam,tower,power station and other structure workshop frames

DIN 6914 – 1989 High-Strength Hexagon Bolts With Large Widths Across Flats For Structural Bolting

① Material:Steel, Strength class 10.9 by DIN ISO 898-1

Let’s first understand what is a steel structure high-strength bolt. It is generally made of heat-treated high-strength steel (35CrMo35 carbon steel material, etc.), which can be divided into 8.8 grades according to the performance grade. Grade 10.9, unlike ordinary bolts, bolts must be above grade 8.8. There is no need to put forward the requirements of steel grade and steel grade when selecting. Friction joints are widely used in steel structure engineering.

Steel structure high-strength bolts can be divided into two types: friction type connection and pressure type connection according to the force characteristics. The connection surface of the high-strength bolt-bearing type connection only needs to be rust-proof. However, friction type high-strength bolts have the advantages of tight connection, good force, fatigue resistance, and suitable for bearing dynamic loads, but the connection surface needs to be treated with friction surface, generally by sandblasting, sandblasting, and then coated with inorganic zinc-rich paint.

Due to the difference in bolt structure and construction methods, high-strength bolts for steel structures can be divided into two types: large hexagonal head high-strength bolts and torsional shear type high-strength bolts. The large hex head type is the same as the ordinary hex head bolts. The bolt head of the torsion scissors is similar to the rivet head, but the threaded end of the torsion scissors has a torx collet and an annular groove to control the tightening torque. This difference requires attention.

The bolt connection pair includes three parts: bolt, nut and washer. The structure and arrangement requirements of high-strength bolts are the same as those of ordinary bolts. Then it must be used according to the specification. Only high-strength bolts of grade 8.8 can be used for large hexagon heads, and high-strength bolts of grade 10.9 can only be used for torsion shear type high-strength bolts.

The preloading of high-strength bolts in steel structures is achieved by tightening nuts. The preload is usually controlled by twisting off the bolt tail using the torque method, angle method or Torx method.

There is currently a special wrench that displays torque. Using the relationship between the measured torque and the bolt tension, torque is applied to achieve the necessary over-tension value.

Corner method The corner method is divided into two steps, one is the initial screwing, and the other is the final screwing. To put it simply, the initial tightening is generally performed by the worker using a common wrench to make the connected components closely fit, and the final tightening starts from the initial tightening position, and the final tightening angle is based on the diameter of the bolt and the thickness of the plate stack. Use a strong wrench to turn the nut and screw it to a predetermined angle value, and the tension of the bolt can reach the required preload value. In order to prevent the torque coefficient of high-strength bolts from changing due to the influence of the external environment, the initial and final tightening should generally be completed within the same day.

The stress characteristics of torsional shear high-strength bolts are the same as those of general high-strength bolts, except that the method of applying pretension is to control the pretension value by twisting the section at the cut. Twist of the bolt.

The friction type high-strength bolt connection completely relies on the friction resistance between the connected components to transmit the force, and the friction resistance is not only the pre-tightening force of the bolt, but also the anti-skid property of the friction surface determined by the surface treatment. The material of the connecting element and its contact surface. coefficient.

After reading it, I believe that everyone has basically understood, where high-strength bolts should be used, and the correct operation and tightening.

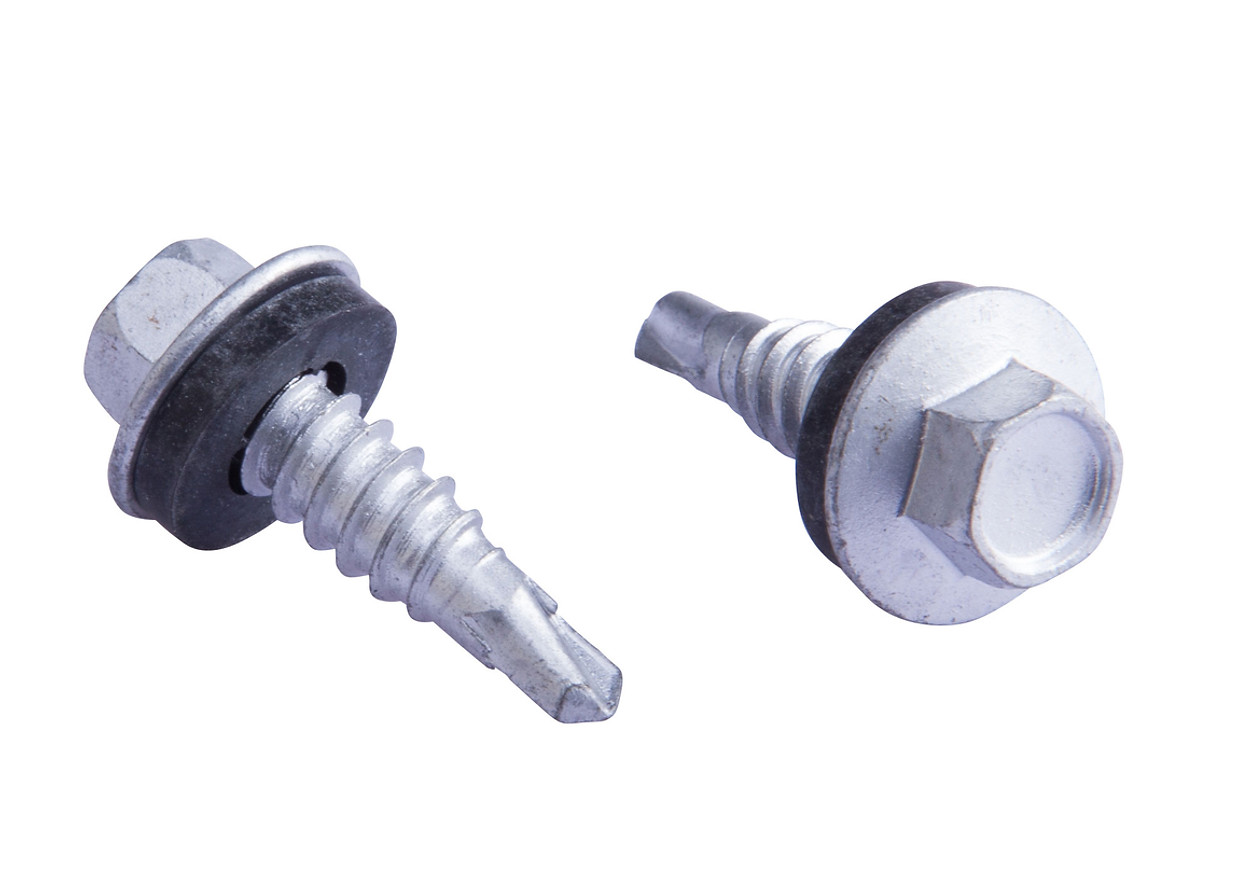

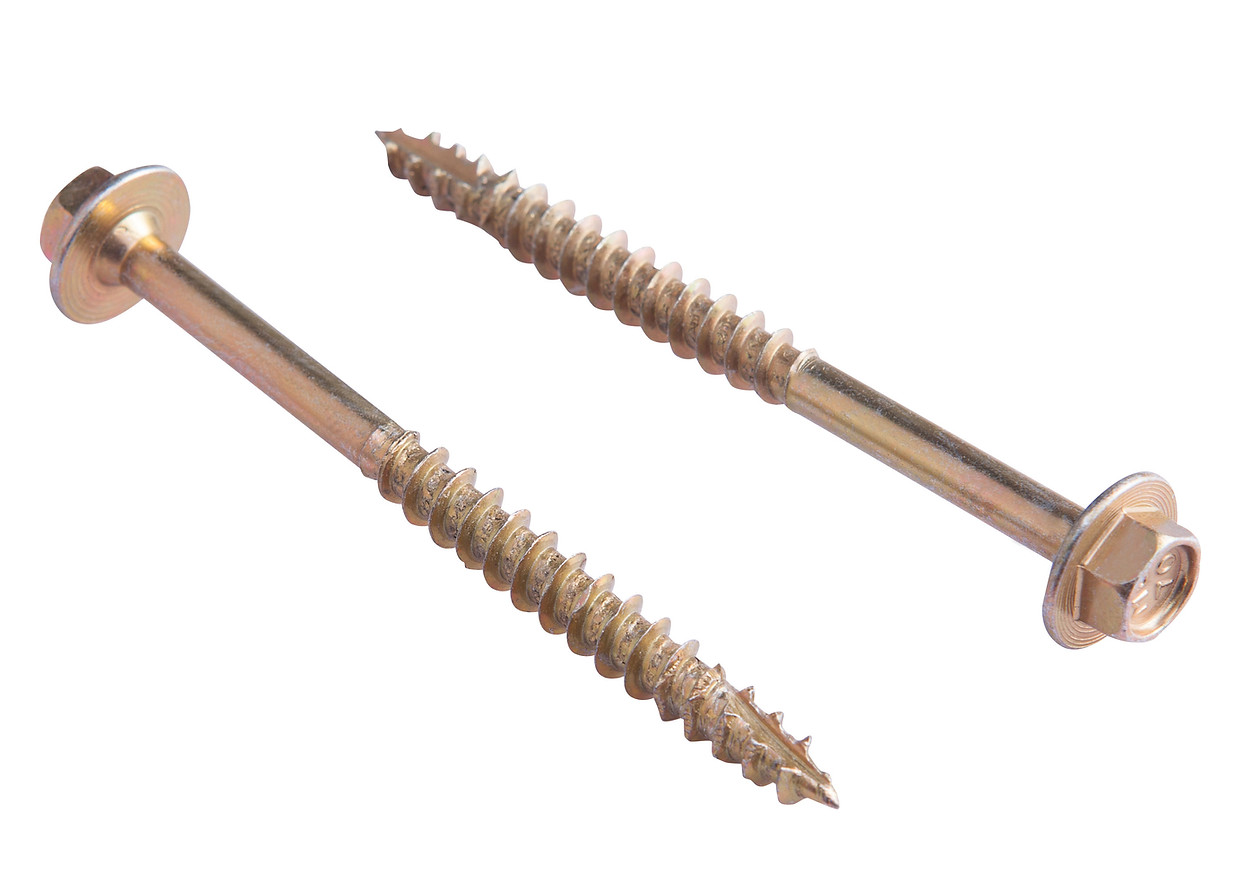

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for High definition Button Head Bolt – Hex Structural Bolt/Heavy Hex Bolt – Zonolezer, The product will supply to all over the world, such as: Colombia, Bahamas, Hongkong, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.