Product name: Hex Thin Nuts/Hex Jam Nuts

Size: M1-M152

Grade: 6,

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Zinc Plated

Norm: DIN439B DIN936

The thin nut and the thick nut are the same except for the height of the hexagon. In some installation environments, the space is not large enough. In order to facilitate installation, the nut is designed to be thinner, so that it can be stuck in the space. This is a last resort. But in some places, there is no space limit, but thin nuts are also designed to be used, so why is this? If you want to know why the torsional strength of the thin nut is not as good as that of the thick nut, but it is still designed and used, first of all, we need to know the law and change of the preload force and the number of cycles of the nut of different thickness.

How to use thin nuts

When the thin nut is used, it is not used alone, but is used together with another standard nut, which has the advantage of preventing loosening. When two thick and thin nuts are matched, there are certain operating specifications. From the above table, we can also see that the thin nut should be placed at the front, that is, the thin nut should be screwed in first, and then the standard nut should be screwed in at the back. Only when the position is placed correctly, the anti-loosening effect will be better. it is good.

It's just that many times, the installation operation process does not pay attention to this matter, and it often happens that the front and rear positions are misplaced. Therefore, many companies directly use two identical standard nuts to install when purchasing, although this will increase a certain procurement cost. , but it also effectively prevents the wrong installation.

In the installation process of some companies, in order to save costs, it is not advisable to use only one spring washer to increase the anti-loosening effect. After a lot of tests, it has been shown that the anti-loosening effect of the spring washer can only be maintained for about a week. , as long as the device vibrates a little, the effect of the spring pad disappears. Therefore, the combination of a thin nut and a standard nut is currently the most effective and convenient way to prevent loosening. We only need to pay attention that the two nuts are rotated and tightened separately. Do not not tighten the first thin nut, and then screw in the second standard nut, which will not achieve the anti-loosening effect. As long as the first thin nut is not tightened, the standard nut at the back, no matter how tight it is, will have no effect. When you go back, you will find that the two nuts will be easily withdrawn at the same time. Stress Criteria for Anti-loosening.

Under normal circumstances, as long as the first thin nut is tightened, and then the second standard nut is tightened, it will act as a lock. loosening occurs.

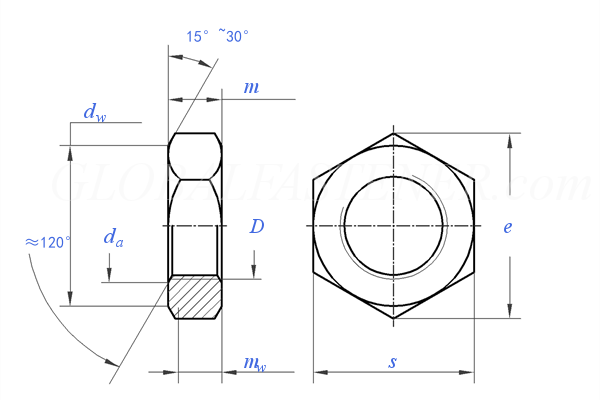

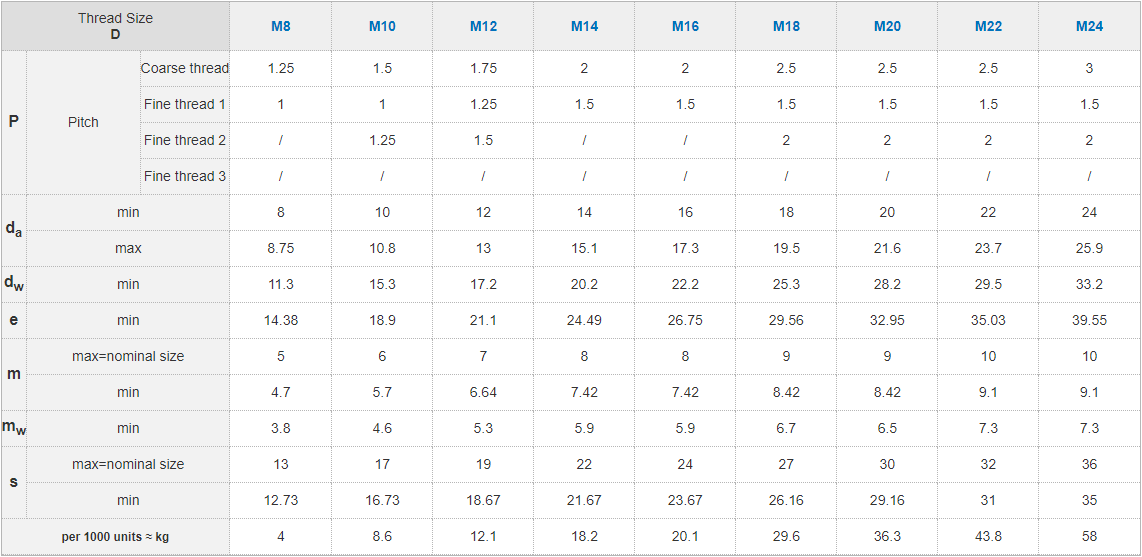

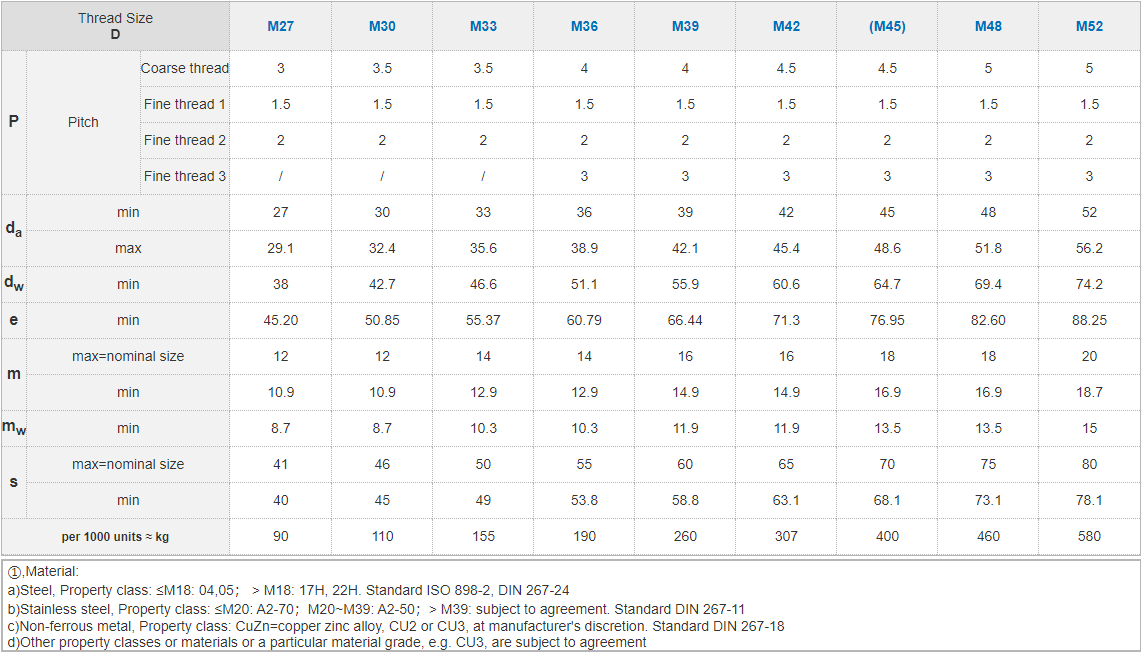

DIN 936 - 1985 Hexagon Thin Nuts—Product Grades A and B,M8 to M52 and M8×1 to M52×3