Product name: Heavy Hex Nuts

Size: M12-M56

Grade: 2H/2HM, DH, Gr. 10

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Black, Zinc Plated, HDG

Norm: ASTM A194, A563, DIN6915

Sample: Free Samples

High-strength nuts are nuts that are made of high-strength steel or require a lot of force to lock. Generally speaking, high-strength nuts are widely used in bridge construction, steel production and the connection of some high-voltage equipment. The standard of high-strength nuts is mainly reflected in its technical requirements, and thickened nuts are generally used. High-strength nuts High-strength nuts are made of high-strength steel, or nuts that require a relatively large force to be locked can be called high-strength nuts. Many high-strength nuts are used in the connection of bridges and rails or some high-voltage and ultra-high-voltage equipment. The fracture mode of high-strength nuts is generally brittle fracture. Generally, in order to ensure the sealing of the container, we require a large prestressing force when installing the high-pressure equipment. The use of high-strength nuts Nowadays, many power generation equipment and vehicles such as airplanes, automobiles, trains and ships are developing rapidly and rapidly, so locking components such as our nuts also need to follow the trend of rapid development in order to further develop. High-strength bolts are mainly used in the connection of some important mechanical equipment, especially the repeated disassembly and assembly and various assembly methods have extremely high requirements on nuts. The surface condition and precision of the thread will affect the use of the equipment and the safety factor. Generally, in order to adjust the friction coefficient and to prevent rusting and jamming during use, it is generally required that a layer of nickel-phosphorus should be plated on the surface. The thickness of the coating is generally controlled in the range of 0.02 to 0.03 mm, and the uniformity of the coating must be ensured, the structure is dense, and there are no pinholes. The technical process of nickel-phosphorus plating of high-strength nuts is composed of three parts. The first is pre-plating treatment, which mainly includes the precision and appearance inspection of high-strength nuts before plating to see if there are cracks or defects, and oil stains can be removed manually, or Removal by immersion, pickling, followed by activation of the nut with electricity and rapid nickel plating; followed by electroless nickel plating treatment process, nickel plating on the nut through a series of chemical methods; The post-treatment process generally includes the process of removing the heat required by hydrogen, polishing, and inspection of the finished product. High-strength nuts need to pay attention to some problems. First of all, it is necessary to pay attention to the quality of surface cleaning, and then the friction coefficient needs to meet the technical requirements. When installing, it is necessary to pay attention to the water-free state, and pay attention to timely maintenance and correction. High-strength nuts The use of standard high-strength nuts is gradually widespread, generally consisting of two strength grades, 8.8s and 10.9s, of which 10.9 is the majority. High-strength mothers transmit external forces through friction and applied force. High-strength nuts are more practical than ordinary nuts. With the advancement of technology and life, the application of high-strength nuts has gradually become more widespread, and now its application and status in the industry is irreplaceable.

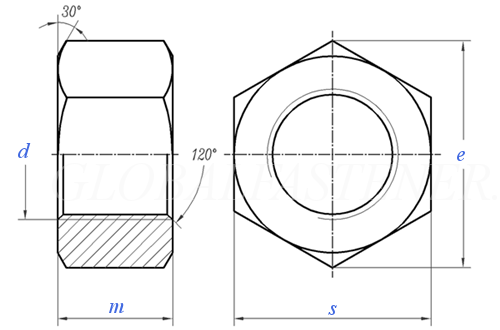

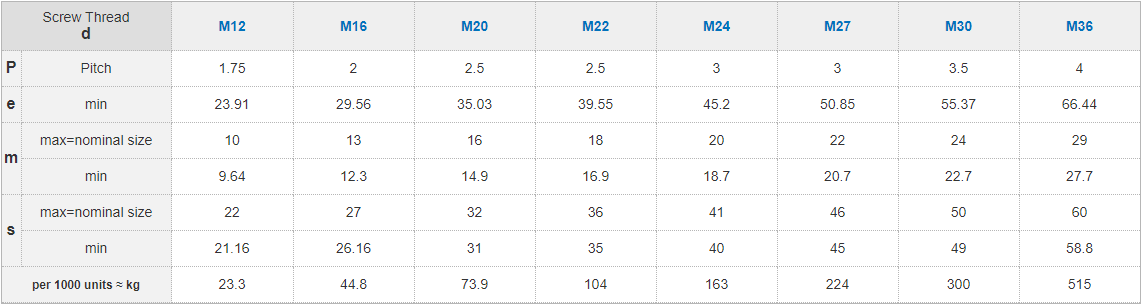

DIN 6915 - 1999 High-Strength Hexagon Nuts With Large Widths Across Flats For Structural Steel Bolting