Factory wholesale Domed Cap Nut - Welding Nuts – Zonolezer Detail:

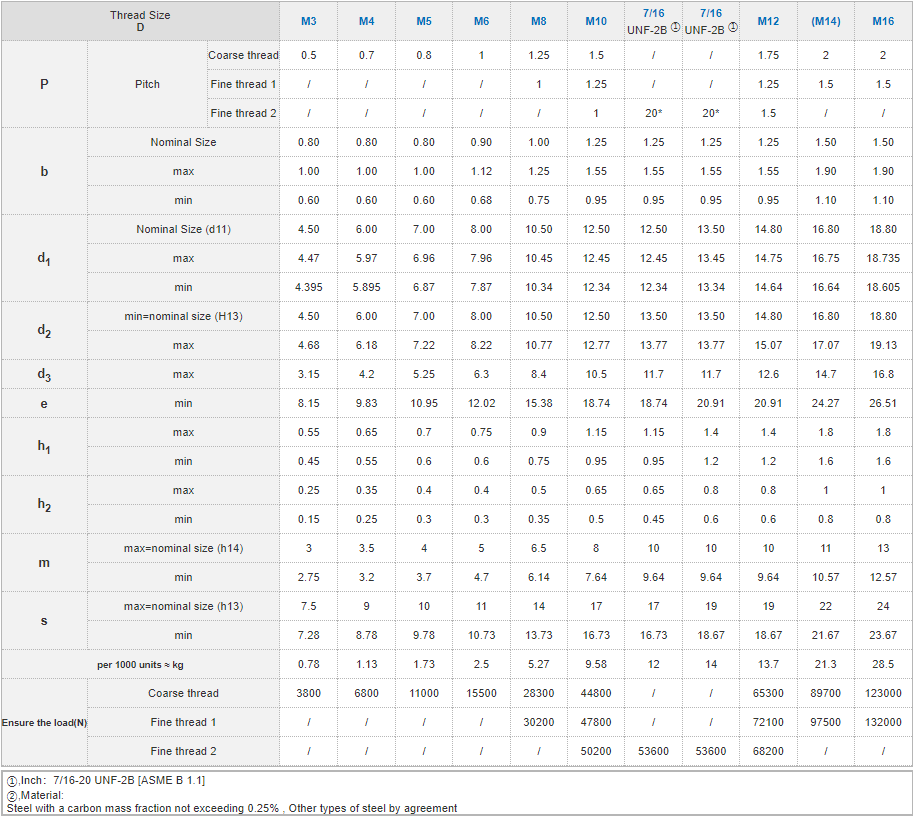

Product name: Welding Nuts

Size: M8-M24

Grade: 6.

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Plain, Zinc Plated

Norm: DIN928, DIN929

Compared with ordinary nuts, welding nuts are more suitable for welding. They are generally made of weldable materials and are thicker and suitable for welding. Welding is equivalent to turning two separate parts into a whole, melting the metal at high temperature and mixing it. After cooling down together, alloys will be added in the middle, and the interior is the effect of molecular force, and the strength is generally greater than that of the parent body. The experiment of welding parameters depends on the fusion size of the weld, and the welding parameters are adjusted according to the fusion size until the defects are eliminated. Of course, the quality of welding is related to the pre-welding treatment, such as cleaning, oil stains, etc. Therefore, the use of weld nuts is very extensive. Precautions for using welding nuts: 1. The shielding gas is argon. 2. The length of the tungsten electrode protruding from the gas nozzle. 3. The length of the welding arc is preferably 2~4mm when welding ordinary steel, and 1~3mm when welding stainless steel. If it is too long, the protection effect is not good. 4. Windproof and ventilation. In windy places, be sure to take measures to block the net, and take appropriate ventilation measures indoors. 5. Use a power supply with vertical external characteristics, and use positive polarity (the wire is connected to the negative pole) when it is DC. 6. It is generally suitable for the welding of thin plates below 6mm, and has the characteristics of beautiful welding seam shape and small welding deformation. 7. In order to prevent the occurrence of welding pores, the welding parts must be cleaned up if there is rust, oil pollution, etc. 8. In order to make the argon gas well protect the welding pool and facilitate the welding operation, the center line of the tungsten electrode and the workpiece at the welding place should generally maintain an angle of 80-85°, and the angle between the filler wire and the surface of the workpiece should be as small as possible. Usually about 10°.

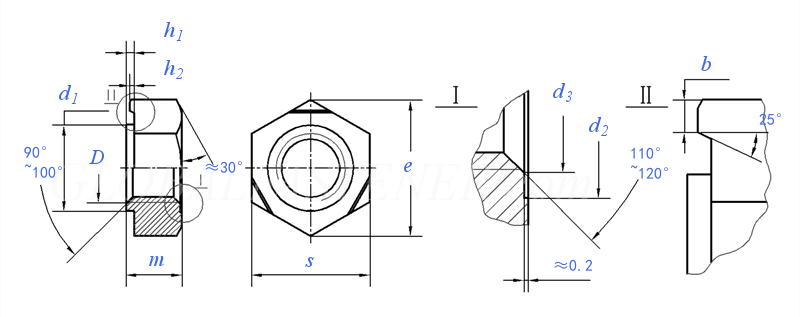

DIN 929 – 2013 Hexagon Weld Nuts

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Factory wholesale Domed Cap Nut - Welding Nuts – Zonolezer, The product will supply to all over the world, such as: panama, Uruguay, Bangkok, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!