2021 Good Quality Din315 Wing Nut - Nylon Insert Lock Nuts – Zonolezer Detail:

Product name: Nylon Insert Lock Nuts

Size: M6-M56

Grade: 6, 8,10, SAE J995 Gr. 2/5/8

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Zinc Plated

Norm: DIN985 DIN982, ASME B18.16.6

Sample: Free Samples

The lock nut is also the nut, which is screwed together with the bolt or screw for fastening parts. It is an original part for all production and processing equipment. The lock nut is the part that tightly connects the mechanical equipment together. , With the help of the threads on the inside, the same specifications and types of lock nuts and screws can be connected together. The following will introduce several methods for preventing lock nuts from slipping. What are the anti-loosening methods of the locking nut?-Zonolezer1. The anti-loosening of the equipment is to use the locking nut stopper to directly limit the relative rotation of the locking nut pair. Such as the application of open pins, serial wires and stop washers. Because the lock nut stopper has no pre-tightening force, the lock nut stopper can only work when the lock nut nut is loosened and returned to the stop position. Therefore, the method of locking the nut does not actually prevent loosening but prevents it from falling. . 2. For riveting punching and anti-loosening, punching, welding, bonding and other methods are applied after tightening, so that the lock nut pair loses the performance of the kinematic pair and the connection becomes an inseparable connection. The disadvantage of this method is that the bolt can only be used once, and the disassembly is very difficult, and the bolt pair needs to be damaged before disassembly. 3. Friction anti-loosening is the most widely used anti-loosening method. This method forms a positive pressure between the lock nut pairs that does not change with the action of external forces, so as to form a friction that can prevent the lock nut pairs from rotating relative to each other. force. This positive pressure can be accomplished by pressing the locknut pair axially or in both directions at the same time. Such as the use of elastic washers, double nuts, self-locking nuts and insert locking nuts. 4. The structure anti-loosening is to apply the self-construction of the lock nut pair, that is, the anti-loosening method of the Down’s lock nut. 5. The edge punching method is used to destroy the thread at the end of the thread after the locking nut is tightened; anaerobic adhesive is generally used for bonding and anti-loosening to apply to the surface of the thread, and the adhesive can be cured by itself after tightening the locking nut. The actual effect of anti-loosening is better. The disadvantage of this method is that the bolt can only be used once, and the disassembly is very difficult, and the bolt pair needs to be destroyed before disassembly.

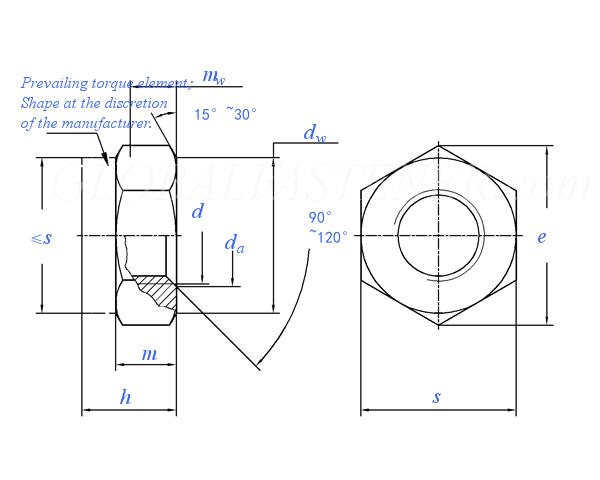

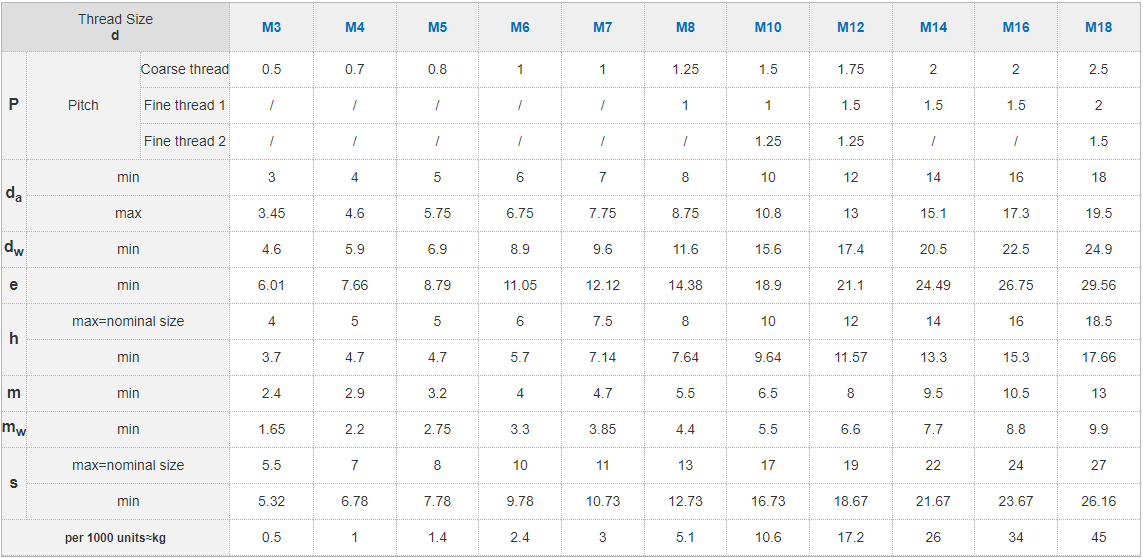

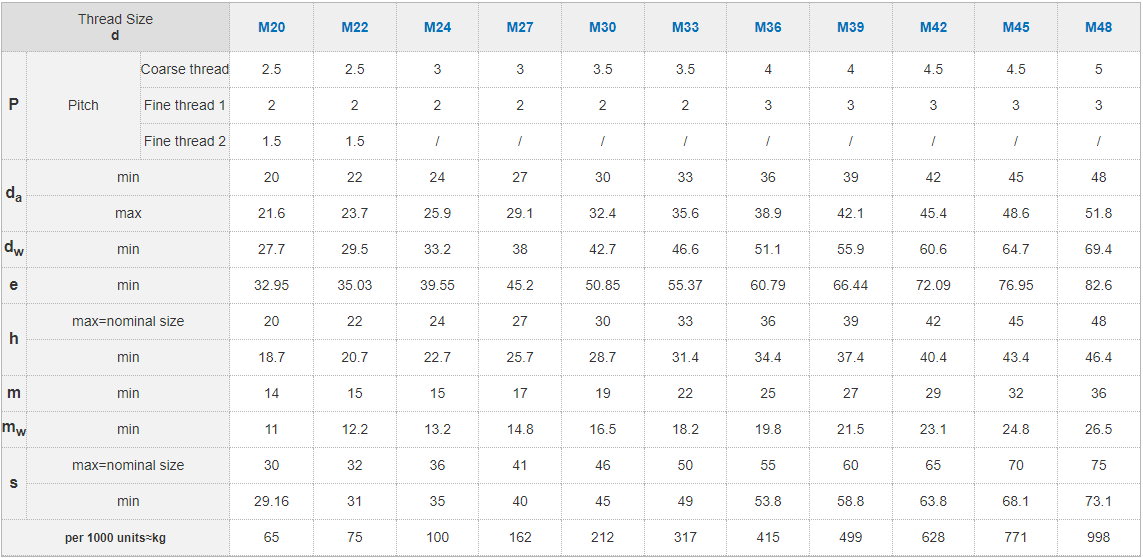

DIN 985 – 1987 Prevailing Torque Type Hexagon Thin Nuts With Non-Metallic Insert

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for 2021 Good Quality Din315 Wing Nut - Nylon Insert Lock Nuts – Zonolezer, The product will supply to all over the world, such as: Casablanca, Adelaide, Bangladesh, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.